11-28-2023

Downloadable Version

Port San Antonio-based XArc/Astroport received $1.3 million in NASA small-business innovation and tech transfer contracts on the heels of Starship rideshare announcement.

(REPRINTED UNDER LICENSE FROM THE SAN ANTONIO EXPRESS-NEWS VIA COPYRIGHT.COM)

By Brandon Lingle, Staff Writer - San Antonio Express-News

A San Antonio-based space startup has received another $1.3 million in NASA funding to continue its work using lunar soil to build structures on the moon. It’s also landed a spot on a rover that’s slated to fly to the moon aboard a SpaceX Starship in 2026.

Astroport Space Technologies and its parent Exploration Architecture Corp., or XArc, landed several small-business innovation and technology transfer awards as part of the $93 billion Artemis program that aims to create a moon base and eventually send humans to Mars.

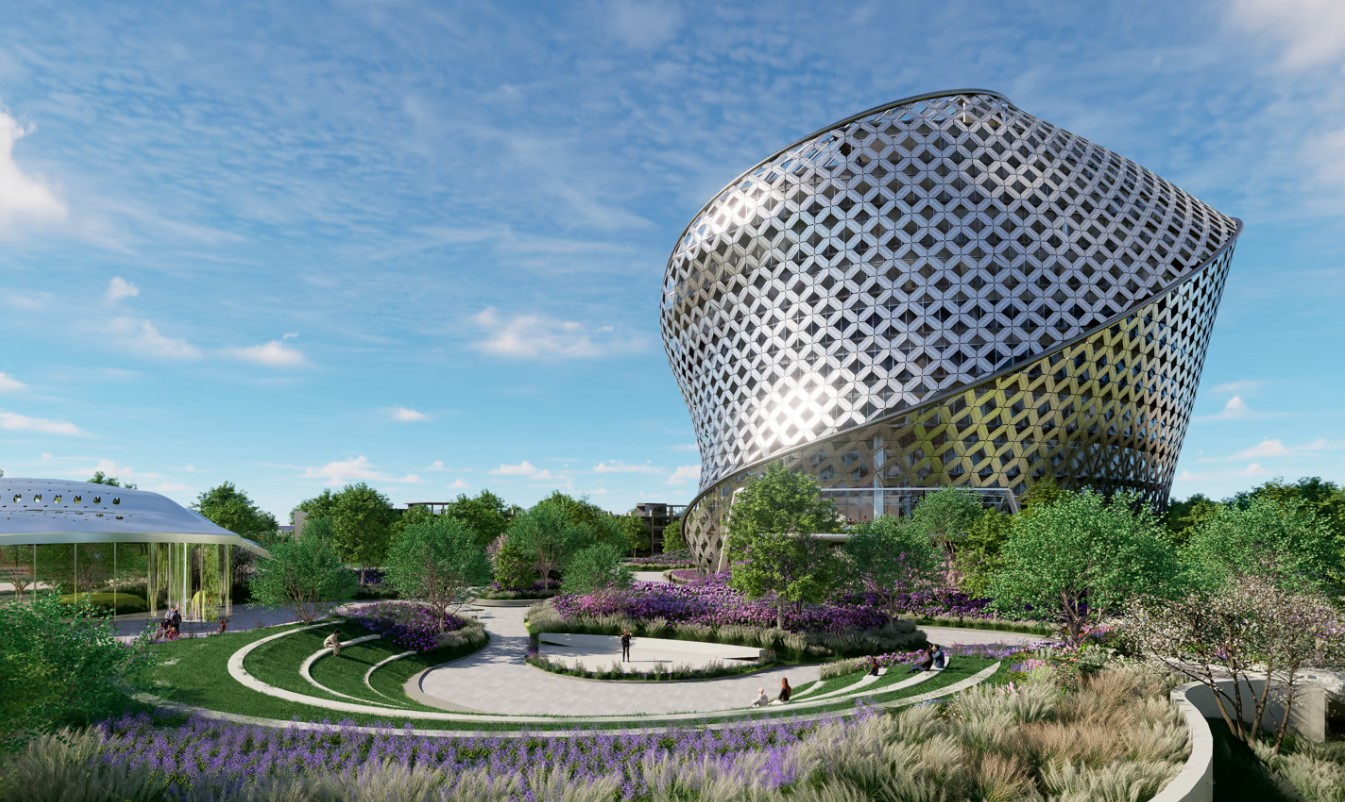

Equipment and materials developed by Astroport, a company based at Port San Antonio, to make bricks and build structures on the moon. The Hyperspace Challenge sponsored by U.S. Space Command recently named the company a finalist for its work developing a system for robots to build structures on the moon using moon dust.

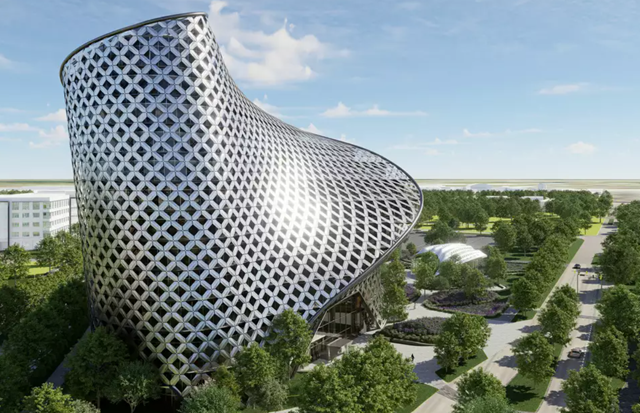

The contracts are the latest wins for the space company that space architect Sam Ximenes founded to help develop safe landing spots for spacecraft on the moon and Mars. He envisions fleets of autonomous robots using molten lunar soil to construct roads, launch and landing pads, and shelters.

“It’s all being validated by NASA that this is an approach that is worth making the investments in,” Ximenes said Monday. “We’re also proud that we’re able to finally get on the lunar surface to start demonstrating these things in the actual environment.”

Exploration Architecture Corp. founder and CEO Sam Ximenes is seen May 19 in his Port San Antonio lab with some of the basalt powder with which his company works. XArc received a $136,000 NASA small business grant to evaluate lunar landing pad construction using technology to melt moon soil, which contains a large amount of basalt, to build landing pads for spacecraft. Image credit: William Luther/San Antonio Express-News.

Astroport has been expanding steadily since its launch in 2020. Ximenes said it’s now growing its footprint at Port San Antonio, where it currently employs 15 people, and has opened offices in Midland, Luxembourg and Australia.

“We need to expand, we’re out of space, and we’re hiring — we’ve been hiring,” he said. “The next step is to make a gravel yard so we can start testing the robots and testing the operations and scenarios we’ve been developing.”

This is the third year in a row XArc/Astroport has received NASA small-business innovation and technology transfer funding.

Bricks and robots

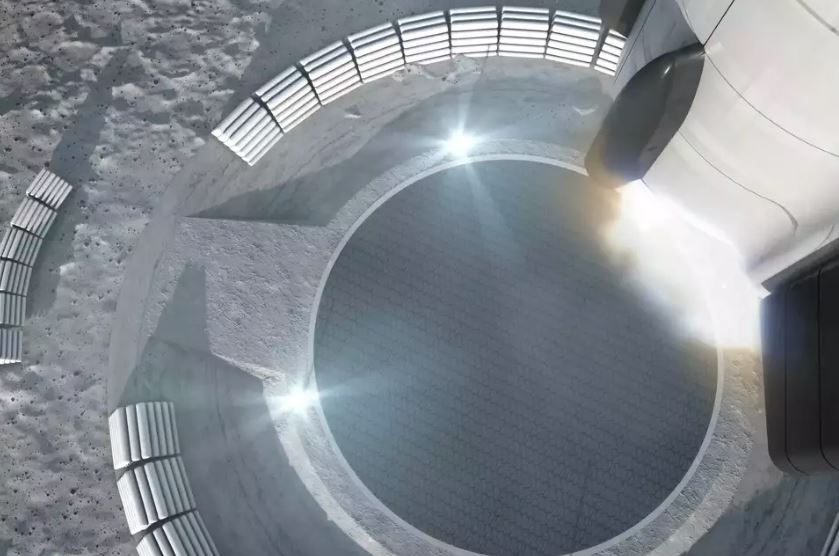

The new awards will go toward Astroport’s continued work on its “Lunatron” furnace-nozzle that makes bricks from molten dust and gravel as well as a new technology to ensure the smooth flow of the grains through the machinery.

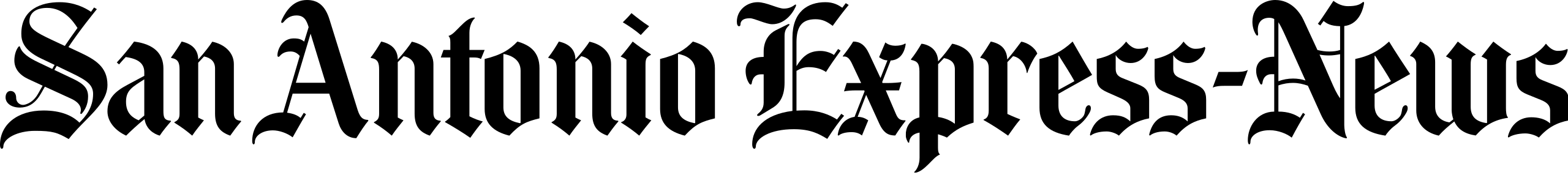

A still from an animation video shows a rocket lifting off from a landing pad made with bricks created from regolith on the surface of the moon. Image credit: Tangram3D.

When the soil — or regolith — is disturbed, electrostatic forces make it cling to equipment, which disrupts the consistent flow needed for melting the soil and using the material for construction.

“We have a somewhat proprietary method to mitigate the electrostatic flow so that we can separate the grains down to the 70-micron level that we need for the bricks,” Ximenes said.

XArc also landed a contract to develop an autonomous surveying robot, “Surveyorbot,” that will evaluate the feasibility of potential lunar construction sites. It will take measurements to determine the soil composition and depth of bedrock before the construction robots arrive.

The Brickbot is a proof-of-concept project to show that regolith bricks can be made on the moon. Astroport Space Technologies officials are targeting 2026 for delivering this test vehicle to the lunar surface.

NASA also invested in Astroport’s continued development of a “concept of operations” to construct lunar landing and launch pads.

A company video about the concept shows a Starship landing on the moon, autonomous rovers offloading equipment and beginning to build infrastructure for a lunar base. They set up shelters, a power grid and communications and begin excavating regolith and constructing roads and other infrastructure.

A still from an animation shows the Lunatron placing newly formed regolith bricks on the surface of the moon. Image credit: Tangram3D.

‘We’re on track’

It looks like science fiction, and it’s happening at Port San Antonio.

“These awards demonstrate our end-to-end systems approach to LLP construction, breadth of technologies and mission applications being developed within the XArc/Astroport company group for advancing state-of-art lunar surface infrastructure construction,” Ximenes said in a statement.

Sam Ximenes, CEO of Astroport Space Technologies, displays a 3D cable hang printer at the The San Antonio Museum of Science and Technology at Tech Port Center + Arena on Thursday, Aug. 11, 2022. Image credit: Billy Calzada, San Antonio Express-News / Staff photographer.

The NASA wins follow the recent announcement that Astroport is part of a commercial mission to the moon dubbed Mission 1. Hawthorne, Calif.-based Astrolab is leading the mission to send the Flexible Logistics and Exploration, FLEX, rover to the moon aboard a Starship, the experimental SpaceX mega rocket.

Astroport’s experiment on the rover will test the “sieving and grain separation technology” that mitigates the regolith’s electrostatic forces.

The rover also will carry some personalized bricks made from “lunar simulant” that will be placed on the moon to mark the start of the “first road on the moon.”

“We’re on track with bringing lunar construction to San Antonio and developing the Artemis program with NASA,” Ximenes said.

Sam Ximenes the CEO Astroport Space Technologies shows a prototype of 3D printer filament made from simulated moon dust. Image credit: Charlie Blalock/ Contributor.